Table of Contents

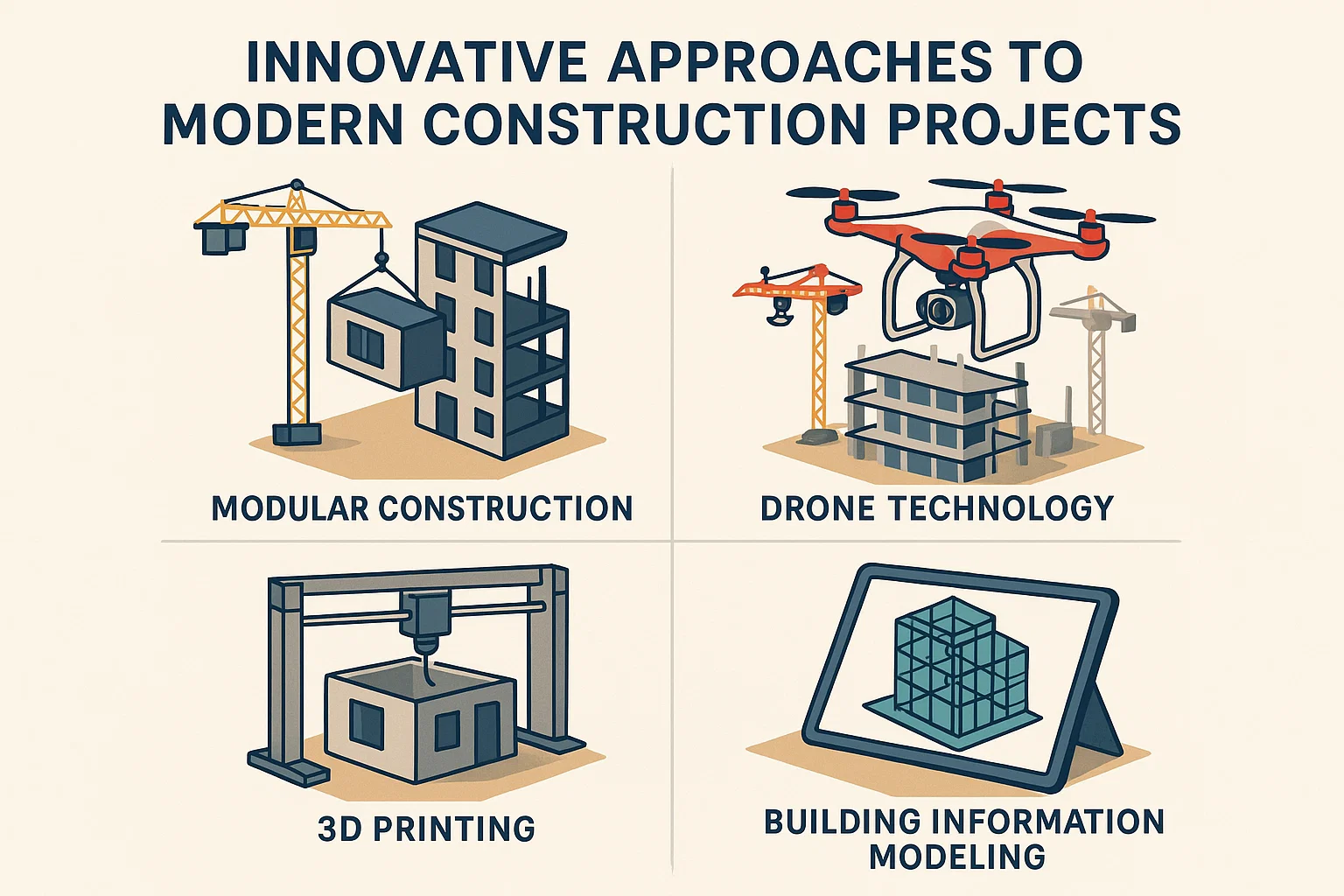

Modern construction is undergoing a remarkable transformation, driven by technological advancements, sustainability imperatives, and safety considerations. Companies and project owners are continually seeking ways to enhance efficiency and minimize environmental impact, with many turning to innovative methods and materials. For anyone planning new builds or renovations, working with an experienced general contractor Fort Mill, SC is key to integrating these innovations effectively and maximizing value.

From eco-friendly materials to robotics and advanced simulations, the industry is witnessing the convergence of engineering ingenuity and digital advancement. Smart investments in digital tools and automated systems are not only streamlining workflows; they are also enhancing productivity. Still, they are also laying the foundation for safer, greener, and more cost-effective construction in the years ahead.

Sustainable Building Materials

One of the most promising shifts in construction is the growing adoption of sustainable building materials. Innovative companies are reimagining waste products, such as insect shells, agricultural byproducts, and recycled plastics, as high-performance construction materials. For example, Miniwiz, a leader in this space, is transforming discarded rice husks and plastic bottles into resilient panels and blocks, making it possible to reduce the environmental footprint of construction without sacrificing durability or safety.

This not only conserves finite natural resources but also aligns with the global push to minimize waste and pollution. Beyond environmental impact, sustainable construction materials are often engineered for superior longevity and efficiency. Many such innovations offer improved insulation, increased moisture resistance, and reduced maintenance costs throughout the building’s lifespan. As the demand for green certifications grows, integrating these materials is becoming essential for competitive, future-ready construction projects.

Autonomous Construction Equipment

Automation is revolutionizing how work is done on construction sites. Autonomous construction equipment—like excavators, bulldozers, and cranes equipped with advanced AI and precision sensors—is now capable of performing repetitive or hazardous tasks with minimal supervision. These intelligent machines consistently outpace manual operators in accuracy, achieving within 1–2 centimeters of designated targets.

The result is significantly reduced human risk and a streamlined build process, as seen in breakthrough projects around the world. Safety on job sites also improves as workers can focus on supervision and value-added tasks instead of performing dangerous, tedious labor. Autonomous vehicles also help optimize resource use by reducing waste through precise grading and excavation, which minimizes the need for rework. As more projects embrace automation, the industry is witnessing a shift towards safer, faster, and more cost-effective delivery.

Digital Twin Technology

Digital Twin technology sits at the cutting edge of architecture, engineering, and construction strategy. A digital twin is an intelligent and dynamic virtual model of a physical project, whether it is a building, bridge, or infrastructure. These comprehensive models use real-time data and AI-driven analytics to simulate scenarios, monitor performance, and optimize ongoing operations.

By integrating digital twins, teams can make better decisions about energy usage, monitor structural health, and address operational issues before they escalate. According to industry experts, digital twins will soon be a standard for complex builds, offering actionable insights throughout a structure’s lifecycle.

Augmented and Virtual Reality

AR and VR are dramatically improving collaboration and client engagement across the construction sector. Augmented reality overlays digital information, such as 3D models, onto live physical environments using tablets or AR headsets. This empowers project managers and clients to visualize finished spaces accurately, make immediate adjustments, and avoid costly mistakes.

Likewise, virtual reality immerses stakeholders in detailed virtual simulations of buildings before a single brick is laid. These technologies not only enhance communication between designers, contractors, and owners but also expedite approval processes and minimize misunderstandings. By visualizing critical decisions in advance, AR and VR are making modern construction more transparent, interactive, and efficient. Don’t miss our recent post about How to Protect Your Driving Record from Costly Penalties.

Robotics in Construction

Advances in robotics are further disrupting traditional construction workflows. Unmanned aerial vehicles (UAVs), for example, are bringing aerial perspectives to worksite management and are even being programmed for precise masonry tasks. These drones autonomously pick and place masonry units, apply adhesives, and handle tasks that are strenuous or risky for humans.

By leveraging robotics, contractors can reduce costs, enhance quality control, and expedite delivery while minimizing risks to workers. Beyond drones, robotic arms are being implemented for everything from on-site steel welding to modular unit assembly in factories, indicating a future where repetitive and hazardous construction activities are largely automated.

Bottom Line

Innovation in construction is no longer optional; it is core to meeting the requirements of an evolving marketplace. Integrating sustainable materials, leveraging automation, unlocking digital twin insights, and embracing AR, VR, and robotics not only modernizes building practices but also actively contributes to safer, more sustainable, and more collaborative project delivery. Keeping current with these trends ensures that every build is resilient, future-proof, and poised for long-term success.