Table of Contents

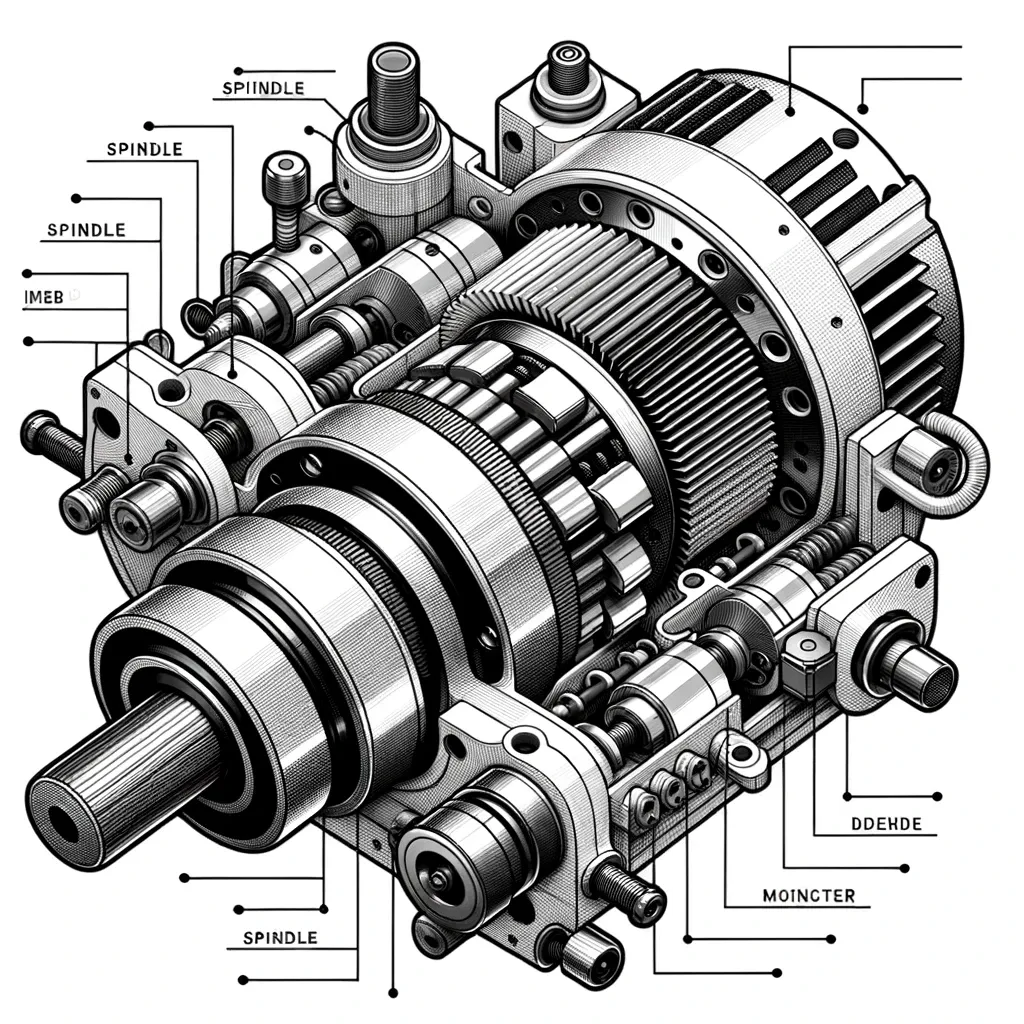

A CNC router spindle motor is a critical component of a computer numerical control (CNC) router machine, a computer-controlled machining device used for cutting, engraving, and shaping various materials, including wood, metal, plastic, and composites. The spindle motor rotates the cutting tool or router bit at high speeds, allowing it to precisely cut or carve the material based on a digital design or program.

Different spindle motors are suitable for specific materials and cutting tasks. For example, some are optimized for wood cutting, while others are better suited for metal or plastic machining.

Like any other machinery, your CNC router will eventually wear down. However, you can get more mileage from your machine by following maintenance best practices.

Clean rust from the spindle taper with a green scotch bright pad and apply a light layer of oil. Do this at least weekly.

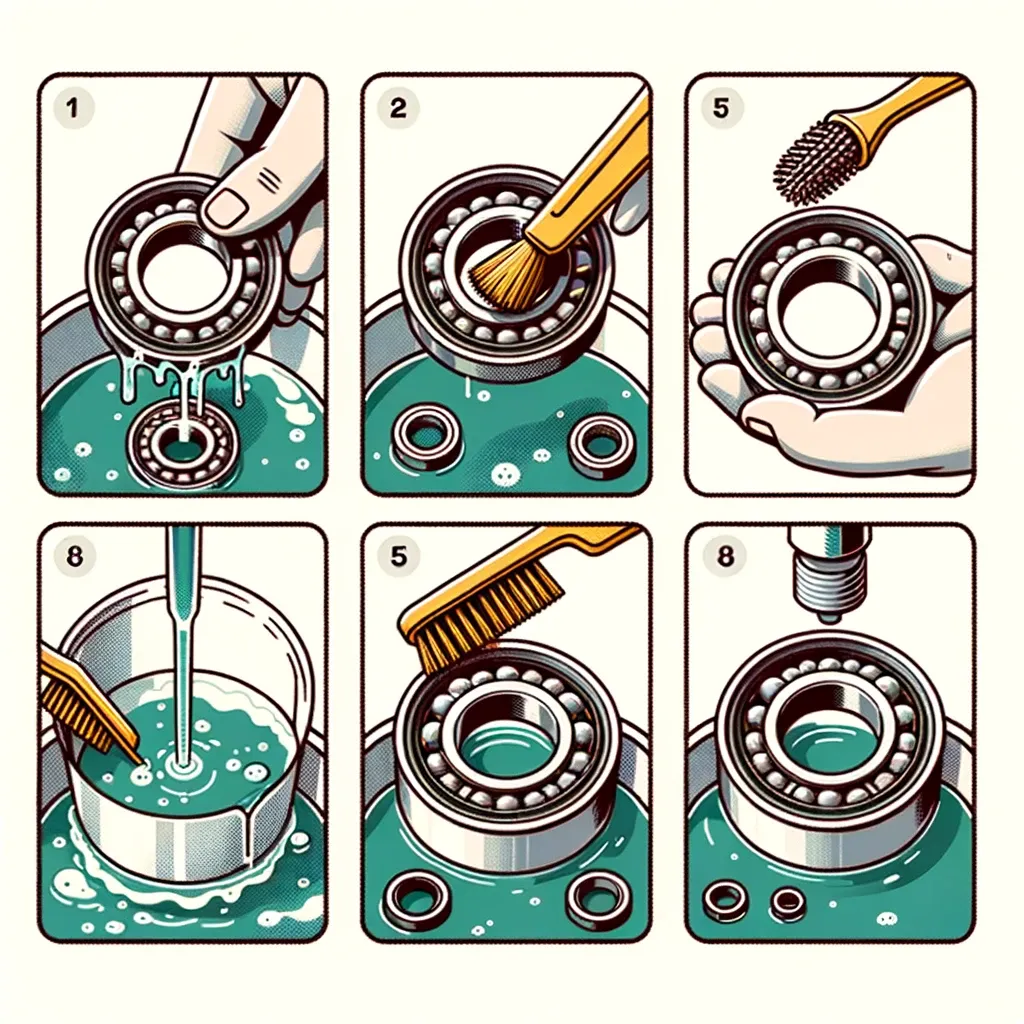

Clean the Bearings

Like a great car, a great spindle will wear down over time if not cared for properly. Regular maintenance can help your CNC router spindle motor last longer and continue to run as smoothly as possible.

One of the most important things to do is routinely clean the bearings. This will lessen friction and increase their lifespan. Using oil explicitly made for spindle drives is also a good idea.

Another thing to do is to watch the temperature of the spindle. If it starts to get hot, this is a sign that there may be a problem. Recording the spindle temperature to compare it to a normal function is also a good idea.

Finally, keeping the collets and tool holders clean is a good idea. This will help to avoid chipping and corroding, which can also shorten the life of the spindle. Click to read Juvenile Jail Food.

Check the Coolant

A CNC router’s spindle is the most critical component in your machine, and it’s the one that will ultimately make or break your ability to deliver high-quality work. Keeping your spindle properly lubricated with a quality coolant is the best way to ensure it lasts.

In addition to keeping your coolant clean, paying attention to how your spindle operates is crucial. Any signs of unusual noise or vibration are often warning signals that the spindle may have a problem.

Paying close attention to your machine and its operation will help you identify problems before they worsen, which can be very expensive to repair or replace. By following these tips, you can extend the lifespan of your CNC router spindle motor and maximize your return on investment.

Clean the Heat Exchanger

The heat exchanger on a CNC router spindle motor regulates temperature levels during extended machining operations. It helps the machine perform consistently at high speeds. For this reason, it should be cleaned regularly. Besides, it also prevents the accumulation of dirt and debris inside the machine.

A cartridge-type spindle is commonly found in industrial applications. It comprises various components, including a pull stud, drawbar clamp, drive pulley, and spindle taper. Each component serves a unique purpose in the machine’s function.

While a spindle is an apt choice for heavy-duty CNC machines, its cost, complexity, and weight might prevent many hobbyists from buying one. As such, they stick with the standard router motor, which offers a lower learning curve and is more affordable. However, the quality of cut edges is much better with a spindle. It’s also ideal for non-ferrous metal machining like aluminum, which demands higher cutting speeds. Most severe CNC professionals opt for a spindle over a router.

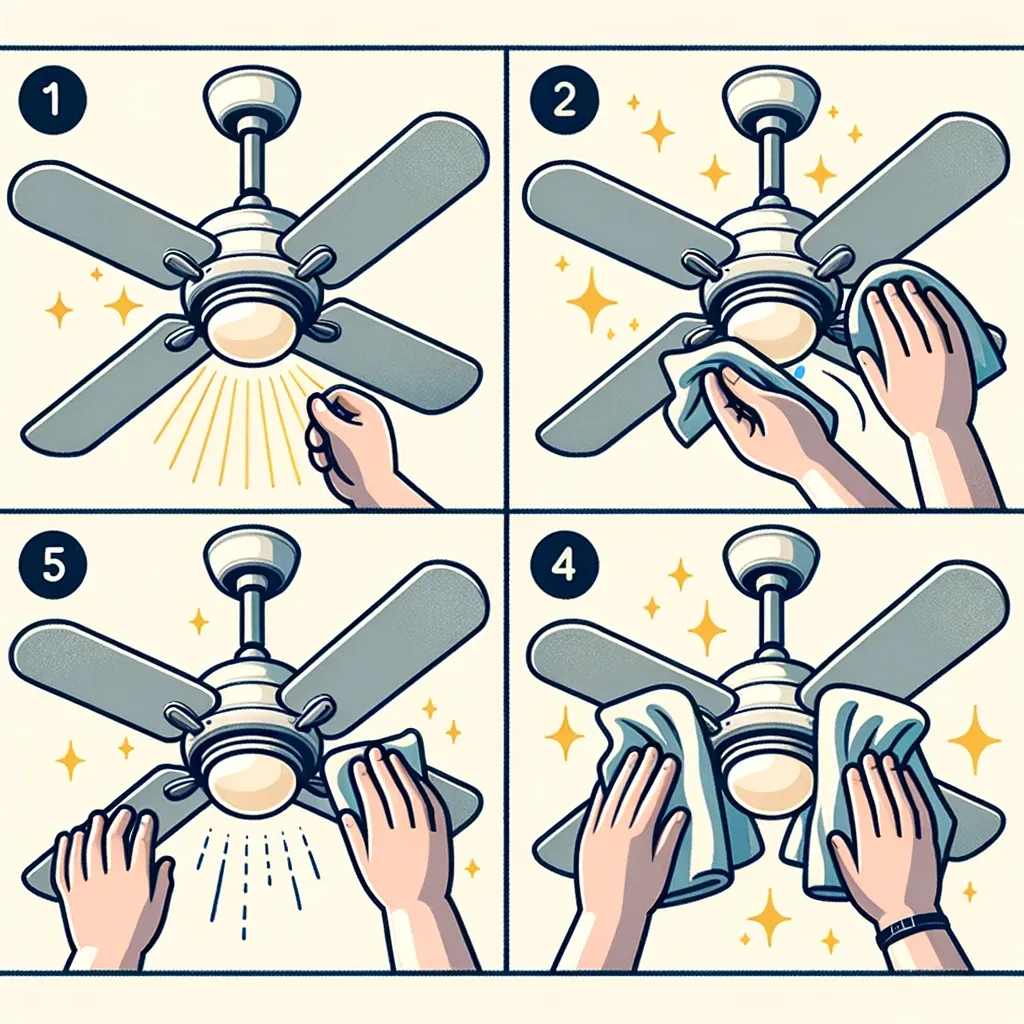

Clean the Fan of the CNC Router Spindle Motor

Using an industrial dust collector is the best way to minimize the amount of debris that enters the spindle motor. Keeping the fan clean is vital, as it can help extend the motor’s life and ensure that all components are working correctly.

It is essential to listen to the spindle during operation and check for uncharacteristic noises. These unusual sounds can indicate a problem and should be investigated immediately. Any cracking, humming, or banging should indicate that the spindle is not performing as expected.

Regular preventive maintenance partnered with proper day-to-day operating techniques can significantly extend the lifespan of your CNC router spindle motor. Increase your machine’s efficiency and profitability while lowering downtime and production lags using these straightforward techniques.

Check the Connections

Keeping your CNC router in good condition will help you maximize the tooling and materials you are cutting. Watching signs of an issue early on and acting quickly will minimize potential damage. In addition to checking for signs of an issue with the spindle, routinely checking the quality of machined parts will give you insights that can help identify and resolve system problems as they arise.

Symptoms include a slow jog of the machine away from home (an axis that has reached its end of travel limit switch).

Check for an open circuit with a multimeter between motor leads or terminals and the motor’s armature. If this reading is not open, the motor needs to be replaced.

Liam Stephens is a dynamic and skilled blogger, recognized for his ability to identify trends and create compelling content. As the founder of Remi-Portrait.com, Liam has become a reliable source of information across various fields such as food, technology, health, travel, business, lifestyle, and current events. He specializes in delivering up-to-date technology news and insights, catering to the diverse community that surrounds Remi-Portrait.com. His proficiency and engaging writing style have earned him a dedicated audience, solidifying his reputation in the digital sphere.